Ultrasonic Flow Meter Working Principle And Applications

CIXI Ultrasonic flow meter is widely used in various production devices of our factory, and the tested media include water, hydrocarbons, lye, etc. Compared with traditional mechanical

flow meter and electromagnetic flow meter, it has high measurement accuracy, strong adaptability to pipe diameter, non-contact fluid, convenient use, easy digital management and so on.

The article discusses the related problems of using ultrasonic flowmeter to measure liquid flow, focusing on the measurement principle, classification, installation and use of ultrasonic flowmeter.

1. Principle of Ultrasonic Flowmeter: Ultrasonic flowmeter is widely used in various production devices of our factory, and the detected media include water, hydrocarbons, lye, etc. When

ultrasonic waves propagate in a flowing fluid, they carry information about the flow rate of the fluid. Therefore, the flow velocity of the fluid can be detected by the received ultrasonic wave

and converted into the flow rate. It can be linked with the water level gauge to measure the flow of open water flow.

The use of ultrasonic flow rate ratio does not need to install the measuring element in the fluid, so it will not change the flow state of the fluid, and does not produce additional resistance.

The installation and maintenance of the instrument will not affect the operation of the production pipeline, so it is an ideal energy-saving flowmeter.

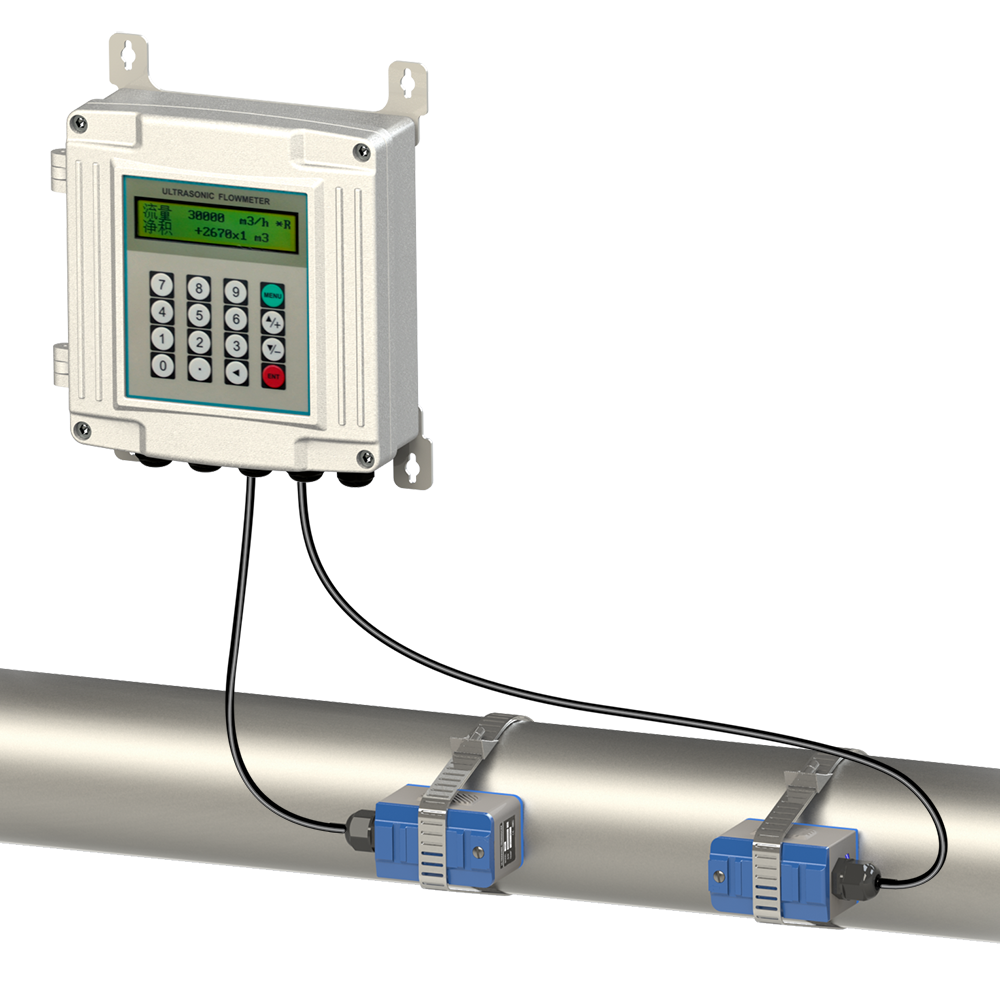

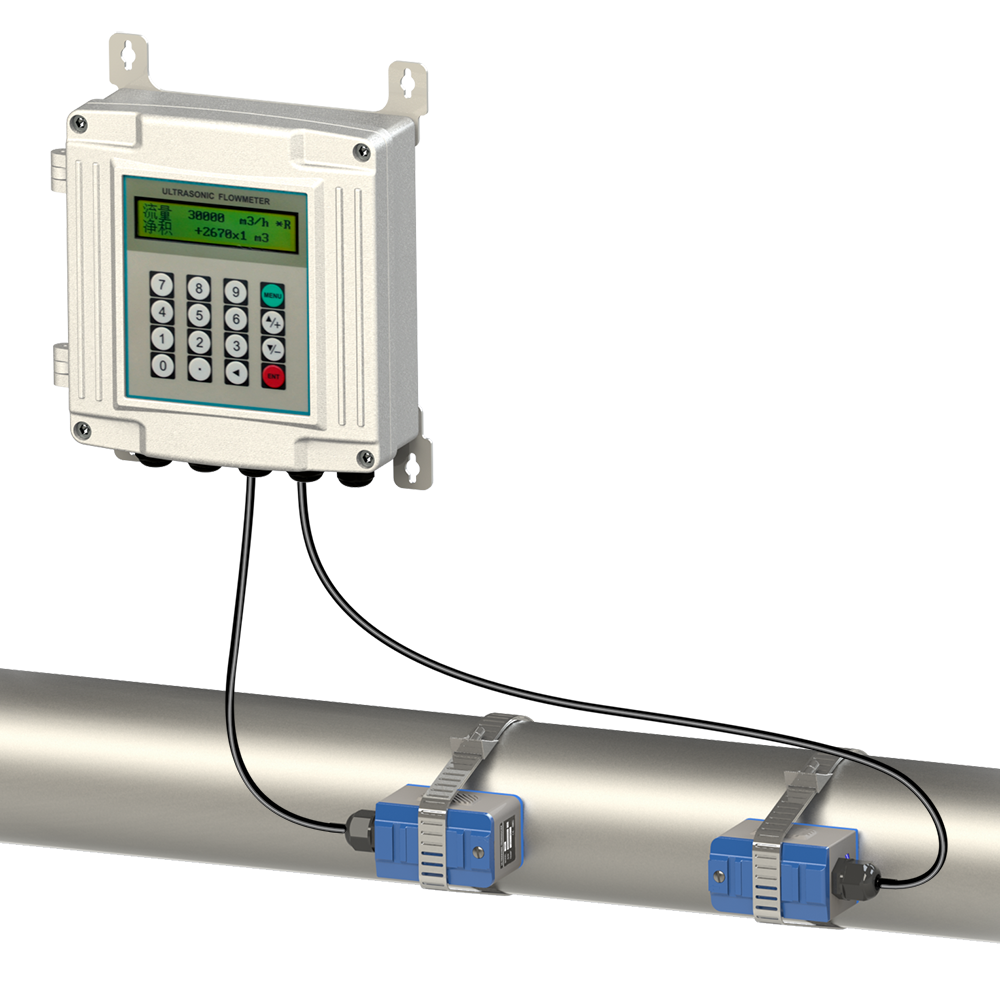

Ultrasonic flowmeter is composed of three parts: ultrasonic transducer, electronic circuit and flow display and accumulation system. The ultrasonic transmitting transducer converts electrical

energy into ultrasonic energy and transmits it to the fluid to be measured. The ultrasonic signal received by the receiver is amplified by the electronic circuit and converted into an electrical

signal representing the flow rate for display and totalizer for display And accumulate. In this way, the flow detection and display are realized.

In addition, the flow measurement accuracy of the ultrasonic measuring instrument is almost not affected by the temperature, pressure, viscosity, density and other parameters of the

measured fluid, and it can be made into a non-contact and portable measuring instrument, so it can solve the problem that other types of instruments are difficult to measure. Flow

measurement problems of corrosive, non-conductive, radioactive and flammable and explosive media. The electronic circuit of the ultrasonic flowmeter includes transmitting, receiving,

signal processing and display circuits. The measured instantaneous flow and cumulative flow values are displayed in digital or analog quantities.

Second, the characteristics of ultrasonic flowmeter:

advantage:

It is a non-contact flow measurement instrument, which can measure the volume flow of liquid and gaseous media. In addition to the advantages of electromagnetic flowmeters

(no pressure loss, no interference with the flow field, measurement of strong corrosive media, impurities and dirt In addition to media, etc., it can also measure the flow of non-conductive media,

and it is not affected by fluid pressure, temperature, viscosity, and density; it has good versatility, and the same meter can measure the flow of media in pipes of different diameters; it is easy to

install and maintain. There is no need to cut off the fluid, and it does not affect the normal flow of fluid in the pipeline. There is no need for valves, flanges, bypass pipes, etc. during installation;

it is especially suitable for flow measurement of large-diameter pipelines. Because there is no pressure loss, the energy-saving effect is significant.

shortcoming:

The installation should not be too close to the vibration source, which will easily affect the measurement of the probe; when measuring the flow of water, because the water is prone to scale in

the pipeline for a long time, it will affect the signal strength of the probe; it is not possible to measure the suspension.

If you are now looking for a suitable ultrasonic flowmeter and want to know more details and quotation, you can consult winny: sales01@cxflowmeter.com